Unlocking Precision: How Metal Cutting Blades Revolutionize Industrial Applications

In today's rapidly evolving industrial landscape, precision engineering is paramount, with the demand for high-quality components driving innovation in manufacturing processes.

Metal cutting blades, essential tools in this domain, have seen significant advancements in their design and functionality. According to a report by MarketsandMarkets, the global metal cutting tools market is projected to reach $100.3 billion by 2024, growing at a CAGR of 6.2%. This surge underscores the critical role that metal cutting blades play in enhancing productivity and precision across various applications, from aerospace to automotive industries. As manufacturers increasingly seek cost-effective and efficient solutions, the evolution of metal cutting blade technology offers unprecedented accuracy and longevity, revolutionizing traditional machining methods and setting new standards for industrial operations.

Metal cutting blades, essential tools in this domain, have seen significant advancements in their design and functionality. According to a report by MarketsandMarkets, the global metal cutting tools market is projected to reach $100.3 billion by 2024, growing at a CAGR of 6.2%. This surge underscores the critical role that metal cutting blades play in enhancing productivity and precision across various applications, from aerospace to automotive industries. As manufacturers increasingly seek cost-effective and efficient solutions, the evolution of metal cutting blade technology offers unprecedented accuracy and longevity, revolutionizing traditional machining methods and setting new standards for industrial operations.

The Importance of Precision in Metal Cutting for Industrial Efficiency

Precision in metal cutting has become essential for enhancing industrial efficiency, especially with the rise of new digital manufacturing technologies. The global demand for metal cutting blades and tools has surged significantly, driven by the need for accuracy and speed in production processes. According to the High-Speed Steel Metal Cutting Tools Market analysis report, this sector is expected to reach USD 13.3 billion by 2035, growing at a CAGR of 3.9%. This indicates a robust market responding to the increasing need for precision in machining operations.

The Machine Tool and Metalworking Exhibition (MWCS) at the 25th China International Industry Fair showcased the pivotal role of high-end industrial machinery in revolutionizing metal cutting applications. Manufacturers are witnessing significant growth elasticity, emphasizing the need for advanced equipment capable of delivering precision cuts. As businesses strive for greater efficiency and productivity, the integration of innovative metal cutting solutions not only improves operational workflows but also enhances the quality of finished products, solidifying their competitive edge in the market.

Choosing the Right Metal Cutting Blade for Different Material Types

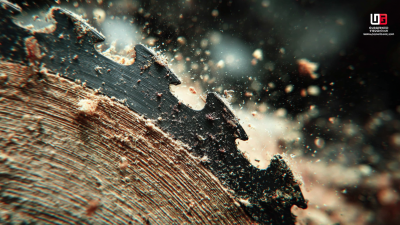

When it comes to industrial applications, selecting the right metal cutting blade is crucial for achieving precision and efficiency. Different materials present unique challenges, and the choice of blade can significantly impact performance. For instance, high-speed steel (HSS) blades are ideal for cutting softer metals like aluminum and brass, as they provide durability and resistance to wear. Conversely, carbide-tipped blades excel when dealing with harder materials, such as stainless steel and exotic alloys, as they maintain sharpness longer and handle increased heat better.

Additionally, the design of the blade must be considered. For example, blades with fewer teeth can effectively cut through thicker materials, allowing for faster chip removal and reducing the risk of blade overheating. On the other hand, blades with more teeth produce smoother finishes, making them suitable for thinner sheets. Understanding the nuances of different materials and blade specifications ensures optimal cutting performance, ultimately leading to a more efficient industrial process.

Factors Influencing Blade Longevity and Performance in Industrial Use

The longevity and performance of metal cutting blades in industrial applications are influenced by several critical factors. Recent research highlights the impact of material properties on blade wear and cutting performance, particularly in the context of multi-blade circular saws equipped with iron-based, multi-layer diamond segments. Experiments indicate that varying rock properties can significantly affect the wear rate and efficiency of these cutting tools, underscoring the importance of selecting the appropriate blade for specific materials.

Moreover, the blade design and its operational conditions play pivotal roles in achieving optimal performance. The Lawn Mower Blade Market is expected to grow substantially, with a projection from USD 1.2 billion in 2024 to USD 1.8 billion by 2033. This growth reflects an increasing demand for blades that not only deliver precision cutting but also exhibit enhanced durability under challenging conditions. As industries continue to innovate and expand, understanding the factors that influence blade longevity will be essential for maximizing productivity and efficiency.

The Impact of Advanced Blade Technology on Production Costs and Quality

The advent of advanced metal cutting blade technology has profoundly influenced industrial applications, particularly in reducing production costs and enhancing product quality. Modern blades are engineered using innovative materials and precision manufacturing techniques, which allow for greater durability and efficiency. This advancements lead to less downtime, as blades require less frequent replacement, ultimately lowering overall operational costs for manufacturers.

Tips: Always ensure that your cutting blades are suited for the specific materials you are working with. Using the right blade can enhance cutting speed and reduce wear, further optimizing your production process.

Additionally, the precision offered by these cutting blades ensures that products meet higher quality standards. When blades maintain their sharpness longer and produce cleaner cuts, it reduces the need for secondary processing tasks, saving both time and resources. Embracing this technology can lead to better product integrity, reduced scrap rates, and increased overall customer satisfaction.

Tips: Regular maintenance of cutting tools is essential. Schedule routine inspections and sharpening to maximize the performance and lifespan of your cutting blades. This practice not only maintains quality but also contributes to cost savings in the long run.

Case Studies: Successful Implementation of Metal Cutting Blades in Various Industries

In various industrial sectors, the adoption of metal cutting blades has demonstrated significant advancements in operational efficiency and precision. Case studies highlight how manufacturers of automotive parts have successfully integrated these blades to enhance their cutting processes, achieving tighter tolerances and reducing waste. Similarly, the aerospace industry benefits from the use of high-performance metal cutting blades, which allow for intricate designs in lightweight materials, thus improving overall fuel efficiency. Such applications showcase the transformative potential of precision tooling in enhancing production standards across diverse fields.

Tips for successful implementation of metal cutting blades include:

1. **Regular Maintenance**: Ensure that blades are regularly inspected and maintained to prolong their lifespan and maintain cutting efficiency.

2. **Material Selection**: Choose the appropriate blade material based on the specific type of metal being cut to optimize performance and reduce wear.

3. **Operator Training**: Invest in comprehensive training programs for operators to ensure they understand the best practices for using and handling cutting blades safely.

As industries continue to advance, the integration of innovative technologies, like those seen in the surgical precision of robotics in rehabilitation or the burgeoning potential of 3D printing in packaging, underscores a paradigm shift that is inevitable. The rise of countries like China, with their burgeoning innovation capacities, further emphasizes the need for continuous adaptation and optimization of manufacturing processes, including the strategic use of metal cutting blades.

Unlocking Precision: How Metal Cutting Blades Revolutionize Industrial Applications

| Industry | Application | Blade Type | Impact | Efficiency Improvement (%) |

|---|---|---|---|---|

| Automotive | Cutting Engine Components | High-Speed Steel Blade | Increased precision and reduced waste | 25% |

| Aerospace | Machining Turbine Blades | Diamond Coated Blade | Enhanced durability and surface finish | 30% |

| Construction | Cutting Building Materials | Tungsten Carbide Blade | Faster cutting speeds and reduced downtime | 20% |

| Metalworking | Precision Sheet Metal Cutting | Laser Cutting Blade | Reduced kerf and waste material | 35% |

| Electronics | Cutting Printed Circuit Boards | Rotary Blade | Improved accuracy and cleaner cuts | 40% |

Related Posts

-

Ultimate Guide to Choosing the Right Metal Cutting Blade for Your Project

-

How to Choose the Right Metal Cutting Blade for Your Projects

-

Essential Techniques for Maximizing the Use of Saw Blades

-

Exploring the Future of Metal Cutting Technologies and Advantages of Best Metal Saw Blades in 2025

-

Ultimate Guide to Choosing the Best Saw Blades for Wood in Your Global Sourcing Strategy

-

10 Reasons Why Saw Saw Blades are Essential for Your Manufacturing Needs