How to Choose the Best Lamination Machine for Your Needs?

Choosing the right Lamination Machine can be a daunting task. Many options exist, making it hard to decide which one suits your needs. According to industry expert John Smith, "A reliable lamination machine is essential for achieving professional results." His insight underscores the importance of selecting the right equipment.

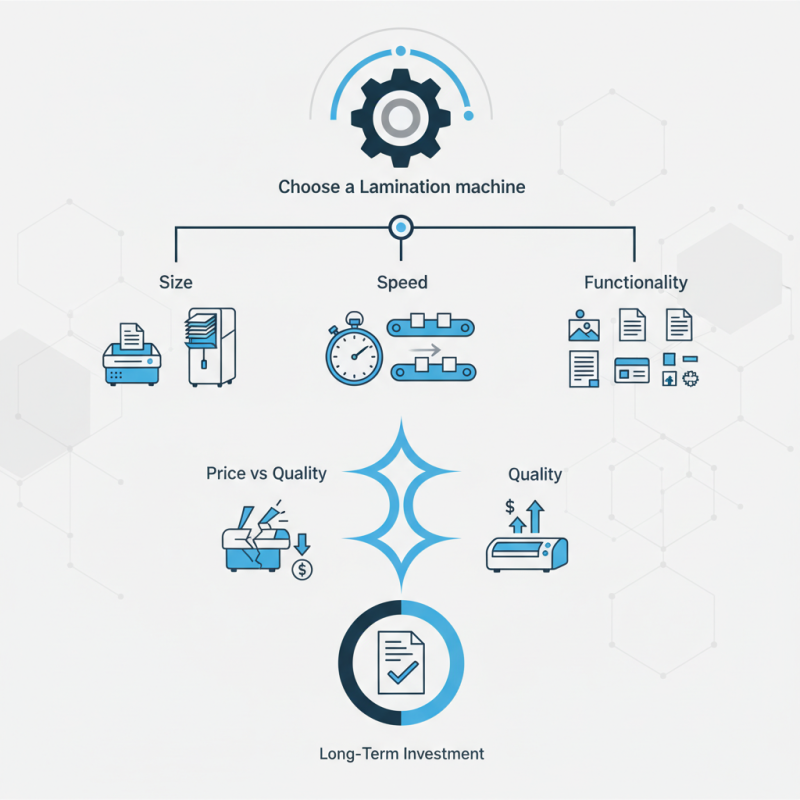

When considering a lamination machine, factors like size, speed, and functionality play a vital role. A compact machine may fit your small workspace better. However, larger projects may demand a more robust option. Imagine needing to laminate crucial documents for a presentation, only to realize your machine can’t handle the volume.

Reflecting on this choice is key. Some users may prioritize price over quality. This can lead to mechanical failures or inadequate results. A more expensive model might seem daunting, but it often provides better longevity and performance. Ultimately, investing in the right lamination machine is not just about the immediate cost; it’s about long-term functionality and effectiveness.

Understanding Different Types of Lamination Machines: Key Features Explained

When choosing a lamination machine, understanding the different types is essential. There are several categories. Each type has unique features and purposes. For instance, pouch laminators are popular for home and small office use. They are simple and easy to operate. Users insert a document into a pouch and feed it through the machine. This process offers convenience but limits size options.

Roll lamination machines, on the other hand, can handle larger projects. They use rolls of film instead of pouches. This is effective for bulk laminating. However, these machines can be tricky to set up. Operators often face challenges with alignment and temperature settings. It's crucial to read the manual thoroughly.

Another option is the cold laminating machine. This type does not use heat, making it safer for delicate materials. It's perfect for photographs and archival documents. However, cold lamination may not provide the same durability as heat sealing. Users often find that the finish is not as glossy. Each type has trade-offs, making it vital to assess your needs carefully. What works for one situation might not suit another.

Evaluating Laminating Thickness: Choosing the Right Film for Your Projects

When selecting the right laminating film, thickness plays a crucial role. The thickness of films is typically measured in mils, with common options ranging from 1.5 to 10 mils. Thinner films, around 1.5 to 3 mils, are ideal for documents that need flexibility, like menus or brochures. They provide a lightweight finish without compromising protection. However, they often lack durability for long-term use.

For projects requiring more resilience, opt for films between 5 to 10 mils. These thicker options serve well for items exposed to wear and tear, such as ID cards or educational materials. A recent industry report highlighted that 57% of businesses prefer films over 5 mils for their longevity. Yet, some may overlook that thicker films can sometimes cause issues with curling and may affect the appearance of printed materials.

Understanding your project's needs is vital. Reflect on how your laminated items will be used. Will they endure daily handling? Consider the environments they will be in. The wrong thickness can diminish the end result. Striking a balance between thickness and flexibility is key to achieving the desired outcome for any laminating project.

Assessing Laminating Speed: How Much Volume Do You Need to Process?

When choosing a laminating machine, assessing speed is crucial. How much volume do you need to process? According to a recent industry report, businesses handling up to 2,500 documents daily require machines with speeds over 15 feet per minute. This is essential for maintaining productivity.

However, speed alone should not dictate your choice. Think about the type of laminating projects your business undertakes. If you focus on smaller batches or specialty items, a slower, more versatile machine may suffice. Some users find that higher speeds lead to frustration with jams and excess waste.

Consider also that most laminating machines can handle different materials. A balance between speed and flexibility may serve your needs better. Remember, selecting a machine that fits your workflow can save time and money. The decision is not just about numbers; it requires careful thought. Aim for a machine that reflects your unique requirements.

Assessing Laminating Speed: Volume Processing Needs

Comparing Cost-Effectiveness: Initial Investment vs. Long-Term Benefits

When choosing a lamination machine, cost-effectiveness is a key consideration. Many buyers focus on the initial investment, but it's essential to think about long-term benefits too. A cheaper machine may save money upfront, but it often leads to higher operational costs later. Think about the materials required for maintenance and the durability of the machine itself.

For example, a low-cost model might be less reliable. This can result in more frequent repairs and downtime. These factors add hidden costs that can offset initial savings. On the other hand, a slightly more expensive machine might offer better features, energy efficiency, and longer longevity. Investing more initially could mean fewer headaches in the long run.

Moreover, consider your operational needs. If you laminate frequently, the costs can stack up quickly with lower-end machines. Evaluate the total operating costs over several years. Reflecting on this can guide you to a better decision. Ultimately, the best choice aligns both your budget and your operational requirements for sustainability.

Identifying Essential Safety Features for User-Friendly Lamination Experience

When choosing a lamination machine, safety features are crucial. Look for machines with an auto shut-off feature. This helps prevent overheating and fire hazards. A protective cover can also prevent accidental burns. Many machines have a safety lock option too. This ensures that the device only operates when correctly assembled.

User-friendly designs are essential for a satisfactory experience. Ensure the machine has simple controls. Complicated interfaces can lead to mistakes. Consider units with clear indicator lights. These indicate when the machine is ready to use. Moreover, robust legs or a non-slip base is vital. This keeps the machine stable during operation.

However, it’s essential to remember safety is a shared responsibility. Even with the best features, users must remain vigilant. Read user manuals thoroughly. Mistakes happen when instructions are ignored. It’s easy to underestimate the risks. We often forget that a moment of inattention can lead to accidents. Reflecting on safety practices can enhance overall user experience.

How to Choose the Best Lamination Machine for Your Needs? - Identifying Essential Safety Features for User-Friendly Lamination Experience

| Feature | Importance | Description |

|---|---|---|

| Auto Shut-Off | High | Automatically turns off the machine after a period of inactivity to prevent overheating. |

| Temperature Control | High | Allows users to adjust the heat settings based on the material being laminated, ensuring better outcomes. |

| Anti-Jam Feature | Medium | Reduces the risk of jams during operation, enhancing user experience and efficiency. |

| Safety Lock | High | Prevents operation when the machine is not secure, protecting users from accidents. |

| Nonslip Base | Medium | Stabilizes the machine during use, which enhances safety and usability. |

| User-Friendly Controls | High | Simplifies the operation process with clear labels and intuitive design. |

| Cooling System | Medium | Helps to quickly cool down the machine after use, preventing damage and ensuring longevity. |