Top Strategies for Choosing the Best Stainless Steel Drill Bits

In the competitive landscape of metalworking, selecting the right tools is crucial for achieving efficiency and precision, particularly when it comes to drilling into robust materials like stainless steel. According to a report by Grand View Research, the global drill bits market is projected to reach USD 13.74 billion by 2025, driven by increasing industrial applications and advancements in manufacturing technology.

Stainless Steel Drill Bits are renowned for their durability and ability to withstand high temperatures and wear, making them an essential choice for both industrial and DIY projects. As the demand for high-quality, reliable drill bits continues to grow, understanding how to choose the best stainless steel drill bits becomes paramount for professionals and enthusiasts alike. This guide will explore effective strategies for making informed decisions in this critical area, ensuring optimum results in your drilling tasks.

Top Considerations for Selecting the Right Stainless Steel Drill Bits for Your Projects

When selecting the right stainless steel drill bits for your projects, there are several critical considerations to ensure optimal performance and durability. One key factor is the bit's material and coating. High-speed steel (HSS) bits often provide a good balance of strength and heat resistance, while cobalt-coated bits can enhance cutting performance on tough materials. According to a report by the Industrial Supply Association, drill bits with cobalt alloy can last up to 30% longer than standard HSS bits, making them an ideal choice for frequent usage in stainless steel applications.

Another important aspect is the size and type of the drill bit. Choosing the correct diameter and length is essential for achieving precise holes without damaging the workpiece. For projects involving hard stainless steel, a split-point design helps initiate drilling without the need for pre-punching, reducing the risk of wandering. Research from the Machinery's Handbook indicates that using the right geometry for drill bits can increase drilling efficiency by up to 50%, significantly cutting down on project time. By carefully considering these factors, you can select the most effective stainless steel drill bits tailored to your specific project needs.

Top Strategies for Choosing the Best Stainless Steel Drill Bits

Understanding the Different Types of Stainless Steel Drill Bits and Their Applications

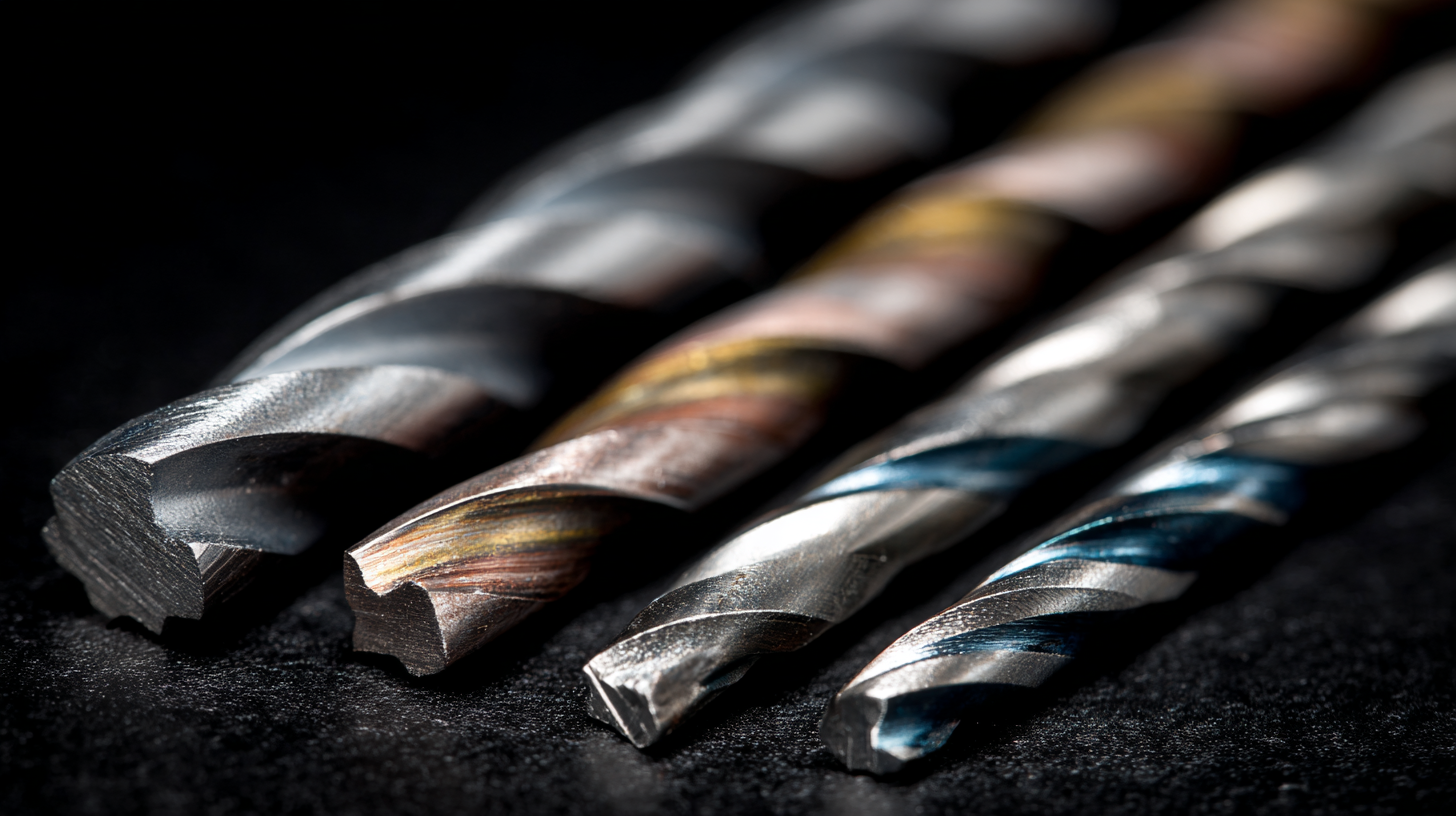

When selecting stainless steel drill bits, understanding the various types and their specific applications is essential for achieving the best results. Stainless steel is a challenging material to work with, given its hardness and resistance to corrosion. Consequently, drill bits designed for this task usually feature high-speed steel or cobalt construction, enabling them to endure the rigors of drilling into tough metals. There are specialized bits, like step bits and hole saws, tailored for creating larger openings or specific shapes, which can also be employed effectively on stainless steel.

Recent advancements in drill bit technology have introduced innovative products that enhance performance. For instance, some new ranges combine multiple functions, allowing for greater versatility when working with stainless steel, mild, and hardened materials. These developments not only streamline the drilling process but also result in increased productivity. When selecting drill bits, consider the specific type of stainless steel you're working with and match it with the appropriate bit design and material to ensure efficient drilling and long-lasting performance.

Top Strategies for Choosing the Best Stainless Steel Drill Bits - Understanding the Different Types of Stainless Steel Drill Bits and Their Applications

| Type of Drill Bit | Material Composition | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Cobalt Drill Bits | High-speed steel with cobalt alloy | Drilling stainless steel, hard metals | Resistant to heat and wear | More expensive than standard bits |

| Titanium Coated Drill Bits | High-speed steel with titanium nitride coating | General-purpose drilling, metalwork | Increased durability and longer life | Coating may wear off over time |

| Carbide Drill Bits | Solid carbide material | Heavy-duty drilling, extremely hard materials | Very hard and can withstand high temperatures | Brittle and can break under stress |

| High-Speed Steel (HSS) Drill Bits | High-speed steel | Wood, plastic, and softer metals | Versatile and cost-effective | Not suitable for very hard materials |

Key Indicators of Quality: Reviewing Hardness Ratings and Coating Technologies

When selecting stainless steel drill bits, understanding hardness ratings and coating technologies is essential for ensuring quality and performance. The hardness of a drill bit significantly impacts its durability and ability to drill through tough materials. For example, drill bits made from high-speed steel often range from 60 to 68 HRC (Rockwell Hardness Scale), indicating excellent toughness and resistance to wear. Reports from industry leaders suggest that bits with a hardness rating above 65 HRC are optimal for heavy-duty applications, ensuring longevity and less frequent replacements.

Coating technologies also play a crucial role in enhancing the performance of drill bits. Coatings such as titanium nitride (TiN) and titanium aluminum nitride (TiAlN) provide improved resistance to heat and friction, extending the lifespan of the bits. Industry studies indicate that bits with TiN coatings can last up to three times longer than uncoated alternatives in materials like stainless steel.

**Tips for Choosing Drill Bits**: Always check the hardness rating before purchasing drill bits; a higher rating ensures better durability. Additionally, consider the coating type—investing in high-quality coated bits can enhance performance and reduce the need for frequent replacements, saving both time and money in the long run. Prioritize brands with a solid reputation in coating technology to guarantee the best results for your projects.

Evaluating Size and Length: How to Choose the Best Dimensions for Precision Drilling

When it comes to precision drilling, selecting the right size and length of stainless steel drill bits is crucial. The diameter of the bit plays a significant role in the hole’s final width, so it's essential to choose a size that aligns with your project’s requirements. Generally, smaller bits are ideal for detailed work, while larger diameters are suited for heavy-duty tasks. Always consider the thickness of the material you are drilling into; as a rule of thumb, the bit should be slightly bigger than the thickness of the material to allow for smooth operation and prevent excessive friction.

Length is another vital factor to consider. Long drill bits are useful for reaching deep into thick materials, but they can be harder to control and may lead to inaccurate drilling. On the other hand, shorter bits provide better control and stability, which is essential for precision work where accuracy is key. Therefore, opting for the appropriate length will depend on both the depth of the hole needed and your ability to handle the drill effectively. By carefully considering both size and length, you can equip yourself with the best stainless steel drill bits for your specific drilling tasks.

Tips for Maintenance and Care: Extending the Life of Your Stainless Steel Drill Bits

To enhance the longevity of your stainless steel drill bits, proper maintenance and care are essential. Research from the National Tooling and Machining Association indicates that regular maintenance can extend tool life by up to 40%. One effective strategy is to ensure that drill bits are clean and free of debris after each use. This not only prevents corrosion but also ensures optimal performance during your next project.

Another crucial tip is to use cutting fluids when drilling. A study by the American Society of Mechanical Engineers highlighted that applying the right lubricant can reduce friction and heat buildup, leading to improved drilling efficiency and less wear on the bits. Additionally, regularly inspecting your drill bits for signs of wear or damage can help you catch issues before they become severe, saving you time and resources.

Lastly, storing your stainless steel drill bits appropriately is vital. Keeping them in a dry, organized toolbox minimizes the risk of accidental damage and exposure to harmful elements that can accelerate corrosion. Investing in protective cases can also further safeguard your tools, ensuring they remain sharp and effective for longer periods.